| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

MIG/MAG welding robot station

01.03 FD-B6 Welbee P400 air cooled, option 02

The mobile welding cell for the craftsman's workshop: simple, inexpensive, safe

72.200,00

EUR excl. Tax / pc(s).

85.918,00

EUR incl. 19% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 1850010

Productdetails

Basic Features

Method

- 131/135

Sheet thicknesses

- 1 – 10 mm

Base materials

- DIN-CEN ISO/TR 15608

Typical applications

- Plant construction

- Series manufacturing

- Pipeline construction

Description

Shortage of skilled labour? Optimized production! Production costs under pressure?

The EASY-ARC welding robot is the answer

Compact, mobile and quickly ready for use

- Cost-effective to purchase

- Ready assembled and documented

- Space-saving and flexible

Time-saving operation

- Simple creation of the welding program via the OTC Easy Teach control system

- No extensive training necessary

Stable, precise welding robot

- Physical relief for employees

- Optimized, consistent welding quality

Safe operation

- Protection against access and glare by electrically monitored lightweight protective housing

- Safety engineering with Monitoring Unit (RMU)

| Cooling | |

|---|---|

| Cooling type | AF |

| Device data | |

|---|---|

| Volume gas cylinder max. | 50 l |

| Dimensions and weights | |

|---|---|

| Power source weight | 62 kg |

| Power source length | 710 mm |

| Power source width | 395 mm |

| Power source height | 592 mm |

| Length approx. | 2140 mm |

| Width/depth approx. | 1380 mm |

| Height approx. | 2200 mm |

| Weight approx. | 1300 kg |

| Duty cycle | |

|---|---|

| Duty cycle at Imax. 40°C | 50 % |

| Current at 60% DC 40°C | 400 A |

| Current at 100% DC 40°C | 370 A |

| Electrical connections | |

|---|---|

| Input current | 22.9 kVA |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Horizontal rotary positioner | |

|---|---|

| Maximum load capacity | 250 kg |

| Rotation speed | 26 °/s |

| Torque | 205 Nm |

| Repetition accuracy | ± 0,1 mm |

| Power consumption | |

|---|---|

| MIG/MAG | 19.2 kVA |

| Setting range | |

|---|---|

| MIG/MAG | 20 – 400 A |

| Switching stages | continuously variable |

| Standards and certifications | |

|---|---|

| Standard | 2006/42/EG |

| Torch | |

|---|---|

| Cooling | gas |

| Torch neck | 45 ° |

| Original equipment contact tip | steel 1.0 mm |

| Maximum load | 350 A |

| Collision protection | B-type integrated |

| Welding robot | |

|---|---|

| Type | FD-B6 |

| Kinematics | vertically articulated robot |

| Number of axes | 6 |

| Working range max. | 1445 mm |

| Maximum load capacity | 6 kg |

| Repetition accuracy | ± 0,08 mm |

| Ambient temperature | 0 – 45 °C |

| Air humidity | 20 – 80 % |

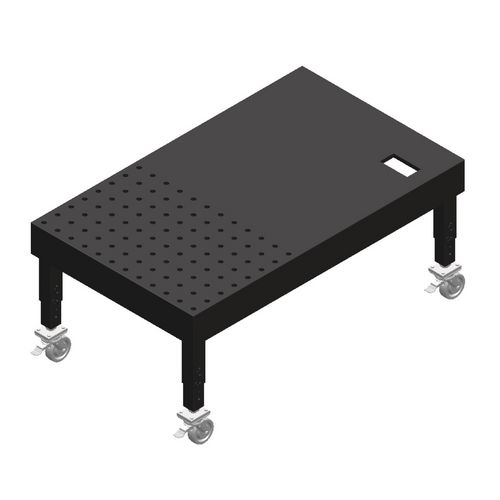

| Welding table | |

|---|---|

| Length | 2000 mm |

| Width | 1200 mm |

| Load capacity approx. | 1000 kg |

| Bore diameter | 28 mm |

| Bore distance | 100 mm |

| Table top material | Steel S355J2+N, plasma nitrided and BAR-coated |

| Table top surface hardness approx. | 450 – 750 Vickers |

| Wire feed | |

|---|---|

| weldable wires steel | DIN EN ISO 14341-A |

| weldable wires stainless steel | DIN EN ISO 14343-A |

| weldable wires aluminium | DIN EN ISO 18273 |

| weldable wires CuSi 3 | DIN EN ISO 24373 |

| weldable wires flux core wire | DIN EN ISO 17632-A |

| Wire feet unit | 4 Rollers |

| Speed | 0 – 22 m/min |

| Wire feed rolls/driven | 2 Rollers |

| VPE | 1 |

Packaging unit: 1

| Cooling | Air |

| Welding device | Welbee P400 (gas-cooled inverter pulse power source) |

| Torch | RT3500H, robot welding torch with forced shutdown |

| Welding Robot | Six-axis robot FD-B6 with integrated cable routing for optimum accessibility |

| Welding table | 2000 x 1200 mm, 3D welding table with intelligent system grids for clamping and positioning workpieces |

| Positioner | Horizontal rotary positioner A2-1PB250 incl. Synchromotion- Software and integration into the Easy Teach control system |

Dr.-Robert-Pfleger-Str. 26

96103 Hallstadt

Deutschland / Germany

info@stuermer-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.