| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

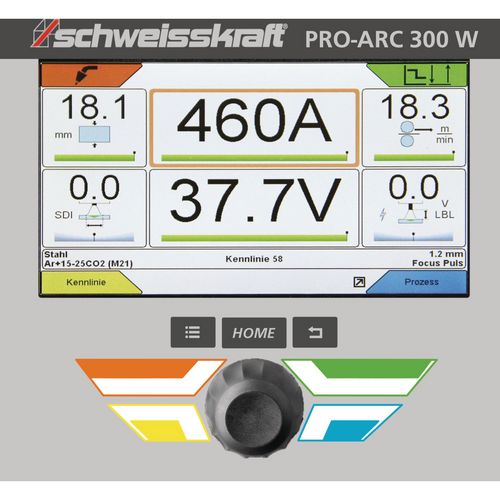

MIG / MAG inverter welding machine

PRO-ARC 400 WS (Profi trolley, control panel on top) Promotional set

Infinitely variable, for perfect MIG/MAG welding results

8.633,00

EUR excl. Tax / pc(s).

10.273,27

EUR incl. 19% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 1086540SET

Productdetails

- Performance increase and quality improvement through digitally controlled MIG/MAG industrial processes

- POWER.ARC: high arc quality, calm, stable and high-energy arc

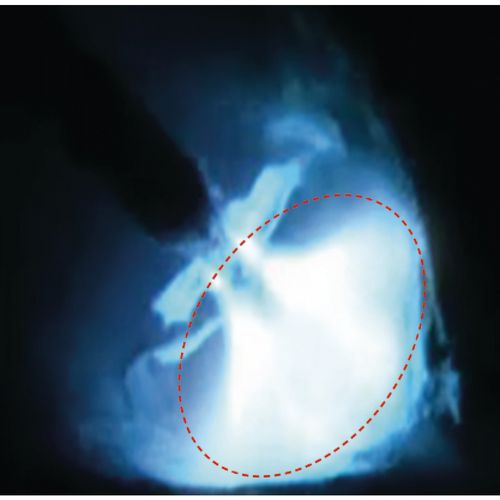

- ROOT: spatter-free welding process for thin sheet metal and root welds with very good gap bridging, safe penetration and significantly higher welding speed for drop welds

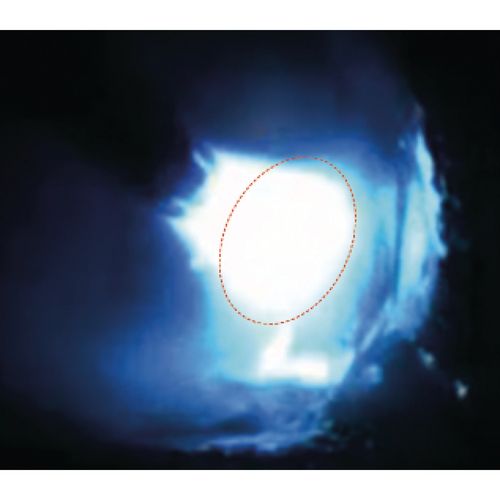

- FOCUS.ARC: Welding with short, powerful arc, safe root penetration, particularly deep penetration, safe flank penetration and reduced penetration notches.

- Increased quality through better visibility into the process, better control over the arc and fewer defects

- SIRIUS user interface for simplified operation of complex processes, easy integration into all systems, production chains and processes via freely configurable interface with full Industry 4.0 capability

- Intelligent, resource-saving water cooling unit: centrifugal pump with high flow rate, energy management measures coolant temperature and cools only when necessary, extending the service life of all components

- Job memory for up to 500 programs

- POWER.ARC: high arc quality, calm, stable and high-energy arc

- ROOT: spatter-free welding process for thin sheet and root welds with very good gap bridging, safe penetration and significantly higher welding speed for drop seams

- FOCUS. ARC: Welding with short, powerful arc, safe root detection, particularly deep penetration, safe flank detection and reduced penetration notches

- SIRIUS user interface for simplifying the operation of complex processes, simple integration into all systems, production chains and processes via freely configurable interface with full Industry 4.0 suitability

- Intelligent, resource-saving water cooling unit: centrifugal pump with high delivery capacity, energy management measures the coolant temperature and cools only when required

| Cooling | |

|---|---|

| Cooling type | AF |

| Torch cooling | water |

| Dimensions and weights | |

|---|---|

| Length approx. | 930 mm |

| Width/depth approx. | 560 mm |

| Height approx. | 1300 mm |

| Weight approx. | 103 kg |

| Duty cycle | |

|---|---|

| Duty cycle at Imax. 40°C | 80 % |

| Current at 100% DC 40°C | 370 A |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Power consumption | |

|---|---|

| MIG/MAG | 16,8 kVA |

| Setting range | |

|---|---|

| MIG/MAG | 20 – 410 A |

| Wire feed | |

|---|---|

| weldable wires steel from to | 0.8 – 1.6 mm |

| weldable wires stainless steel from to | 0.8 – 1.6 mm |

| weldable wires aluminium from to | 0.8 – 1.2 mm |

| Wire feet unit | 4 Rollers |

| VPE | 1 |

Packaging unit: 1

- Feed rollers 1.0/1.2 mm

- Trolley Profi

- Cover flap for control panel

- VarioProtect XXL-W

| Type of construction | with wire feed case |

| Volume gas cylinder max. | 50 l |

| Burn-in stabilizer | ✔ |

| Mains voltage compensation | ✔ |

| FOCUS.ARC | ✔ |

| ROOT | ✔ |

| POWER.PULS | ✔ |

| POWER.ARC | ✔ |

| Process MIG/MAG | ✔ |

| Process MMA | ✔ |

Dr.-Robert-Pfleger-Str. 26

96103 Hallstadt

Deutschland / Germany

info@stuermer-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.