| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

CNC portal milling machine

OPTImill FP 1700

SIEMENS CONTROL 828D

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3511610

Productdetails

- Perfect structures and robust construction guarantee maximum rigidity and stability.

- All main components - bed, work table, column, crossbeam, saddle and headstock are made of high-quality MEEHANITE® quality castings

- Generously dimensioned guides in the X, Y and Z axes

- All guideways are hardened and ground (HRC50 -HRC55).

- The X and Y axes are equipped with with roller linear guide. As a result, the axes move with the highest precision even at high speed.

- Greatest machining accuracy and high damping thanks to wide, adjustable flat guides of the Z-axis for high drilling and milling performance with high spindle output torque

- Hardened and precision ground recirculating ball spindles mounted in high-precision bearings in all three axes for high rapid traverse speeds

- Cooling of the main spindle gear (gears, bearings, spindle) through an oil circulation system. Reduction of thermal expansion

- Operating status display (end of work light)

- Axle covers

- Work lamp

- Air pistol/water pistol

- Heat exchanger

- Spindle holder SK50 with a maximum spindle speed of 8,000 rpm with 2-stage gear for high precision

- Pneumatic counterbalance of the Z-axis ensures very high reliability and stability while multiple axes work at the same time. The SCBS system does not require an additional power supply or drive. This balance system achieves high speed and high processing precision

- Complete machine cladding with wide opening doors for ergonomic workpiece handling

- Automatic lubrication system with pressure control system

- Separation system for lubricating oil and coolant

- Installation elements

SINUMERIK 828D - The power pack in the compact class of CNC controls

Increased productivity and precision in production

- With CNC SINUMERIK 828D control from SIEMENS, users benefit from the fast and sophisticated hardware. It offers maximum ease of use and ensures good connections to a wide variety of storage media and networks. The basic structure of the CNC control corresponds to the standards of normal NC technology.

- As a top specialist for sophisticated milling machines, the Siemens SINUMERIK 828D masters all imaginable drilling and milling operations. Of course, this also applies to any pivoted workpiece planes and to cylindrical workpieces. You don't even need a special CNC control for mold making applications. The unique performance of the SINUMERIK 828D guarantees mirror-smooth surfaces with a minimum of machining time.

- For ergonomic operation and programming, the SINUMERIK 828D is equipped with a large 10.4-inch graphic color screen. Robust function keys and a complete QWERTY keyboard on the terminal enable the user to program, set up and operate even in a rough workshop environment. The mechanical keys are protected against dust and liquids in accordance with IP 65 by a stable and durable film.

- Since the SINUMERIK 828D works without components that are subject to wear, such as fans and hard drives, it is permanently maintenance-free and reliable. Powerful computers and memories enable modern NC strategies to be processed quickly and extensive color graphics to be displayed in real time, including in animated form. On the one hand, this increases the machining accuracy, and on the other hand, it simplifies operation, programming and diagnosis. The computing and storage capacity is so generous that moving graphics can be generated and shown for all functions as an aid as well as for programmed processing.

Control

- 10.4" color display

- 4:3 format

- User-friendly SINUMERIK Operate software

- Front interfaces: USB 2.0, RJ45 Ethernet, Compact Flash (CF) card

- With the 8 horizontal and 8 vertical softkeys you can access all operating masks with just a few keystrokes

- Durable and robust

COMPLETE PACKAGE

- Safety Integrated

- Residual material detection and processing

- ShopMill machining step programming

- Manage network drive

- 3-D simulation

- Simultaneous recording

- System software SW 26x

SIEMENS SAFETY INTEGRATED - Setup with the door open

Functional safety also protects against high costs!

Machine and system safety is not only important because strict regulations have to be observed. If everything runs smoothly, you benefit from time savings in engineering, higher system availability and more investment security.

Extended warranty

With the extended warranty you protect your new machine against warranty damage for a further 12 or 36 months (only to be bought with purchase of machine).

- 12 months; Article No. 3589020

- 36 months; Article No. 3589022

Equipment

Tool changer

- Changer driven by a precision cam for quick and precise tool positioning.

- During the tool change, the tools are transferred directly from the tool magazine to the spindle using a double gripper.

- The tool is selected bidirectionally on the shortest path

- The tool magazine is located outside of the work area

- The cover on the tool magazine protects the tools from chips or coolants

Spindle

- Rigid spindle head

- Automatic compensation system (SCBS) on the spindle head

Stand and crossbeam

- From one piece

Base

- Heavy design and heavily ribbed construction

- Solid one-piece box construction for maximum stability when loading very large workpieces

Work area

- Extra wide work area

Chip disposal

- Conveyor spirals on both sides of the machine base transport high volumes to the chip conveyor

Spindle head

- ZF gearboxes for high speeds

- Oil bath lubricated

- Efficient cooling of the workpiece using internal spindle cooling

- Longer service life and high accuracy

Z-axis

- High rigidity and stability

- Box-shaped design

- Stability even with heavy-duty machining

Spindle

- Spindle with high torque ideal for high-performance machining

- Large speed range up to 8,000 rpm for heavy-duty machining and precision machining

- Automatic oil lubrication of the spindles with cooling

- Inline spindle SK 50

- Cam gear

Gear

- Gear with high transmission ratio

Z-axis

- Pneumatic forward counterbalance in the Z-axis for high dynamics

| Control | |

|---|---|

| Type | Sinumerik 828D |

| System software | SW 26x |

| CNC memory | 5 MB |

| Set change time | 2 ms |

| Look Ahead | 100 |

| Number of tools | 256 |

| Cooling lubricant system | |

|---|---|

| Tank capacity | 900 l |

| Dimensions and weights | |

|---|---|

| Length approx. | 6000 mm |

| Width/depth approx. | 4500 mm |

| Weight approx. | 17000 kg |

| Electrical connections | |

|---|---|

| Total rated value | 50 kVA |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed | |

|---|---|

| X axis | 20000 mm/min |

| Y axis | 20000 mm/min |

| Z axis | 20000 mm/min |

| Feed force | |

|---|---|

| Feed force X-axis | 24.1 kN |

| Feed force Y-axis | 28.9 kN |

| Feed force Z-axis | 28.9 kN |

| Feed motor torque | |

|---|---|

| X axis continuous operation S1 | 48 Nm |

| Y axis continuous operation S1 | 48 Nm |

| Z axis continuous operation S1 | 48 Nm |

| Milling table horizontal | |

|---|---|

| Table length | 1700 mm |

| Table width | 1200 mm |

| Min. clearance vertical spindle - milling table | 50 mm |

| Max. clearance vertical spindle - milling table | 900 mm |

| T-groove size | 22 mm |

| T-groove number | 7 |

| T-groove spacing | 150 mm |

| Max. load bearing capacity | 5000 kg |

| Distance between columns | 1400 mm |

| Pneumatic connection | |

|---|---|

| Operating pressure | 6 bar |

| Precision | |

|---|---|

| Repetition accuracy | ±0,008 mm |

| Positioning accuracy | ±0,008 mm |

| Travel | |

|---|---|

| X axis automatic | 1700 mm |

| Y axis automatic | 1400 mm |

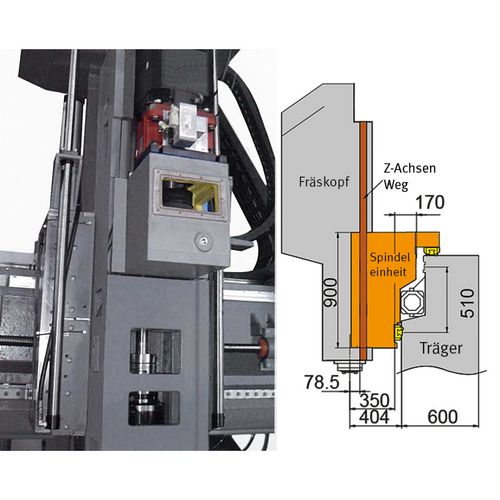

| Z axis automatic | 850 (1050 optional) mm |

| Max. distance spindle to column | 404 mm |

| Turret | |

|---|---|

| Design | Double arm gripper |

| Number of tool slots | 32 Tools |

| Max. tool diameter adjacent slots free | 250 mm |

| Max. tool diameter | 160 mm |

| Max. tool length | 350 mm |

| Max. tool weight | 15 kg |

| Vertical spindle | |

|---|---|

| Spindle chuck | SK 50 DIN 69871 |

| Speed range | 8000 min¯¹ |

| Explanation speed range | Please note that the maximum spindle speed must be reduced by approx. 20 % in continuous operation. |

| Drive motor output continuous operation S1 | 15 kW |

| Drive motor output S6-30 % operation | 22.5 kW |

| Torque drive motor continuous operation S1 | 126 Nm |

| Torque drive motor S6-30 % operation | 380 Nm |

| VPE | 1 |

Packaging unit: 1

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.