| Dimensions and weights | |

|---|---|

| Width/depth approx. | 2400 mm |

| Height approx. | 1900 mm |

Motorized swing bending machine

Very high flexibility and time savings due to swiveling upper beam with two mold stations

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Productdetails

Standard equipment:

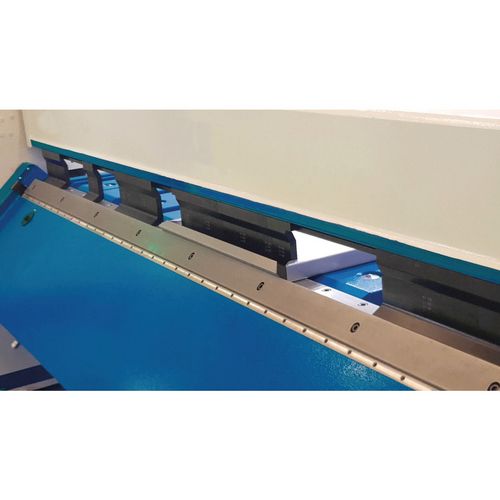

- Clamping beam with eccentric drive for fast clamping and opening cycle.

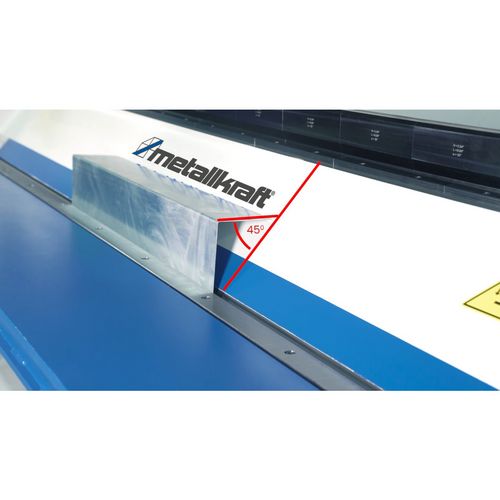

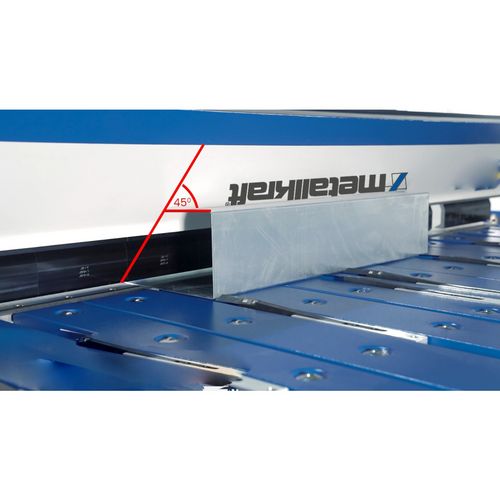

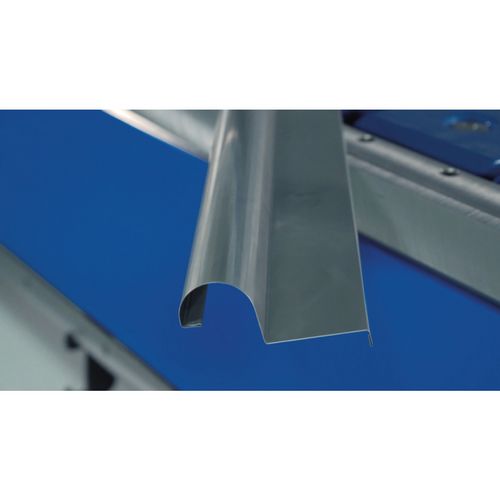

- 180° swiveling upper beam with two work stations - 100mm high segmented goad feet and one-piece 30° sharp bending rail

- Large, clear upper beam opening at 200mm

- One narrow and one wide continuous bending bar included (10mm and 25mm)

- Manual sheet thickness adjustment of the bending beam

- Front safety area secured by light curtain

- 3-position foot pedal for one-man operation

- Servo-motorized backgauge with 1000mm travel range with flat, rotating stop fingers

- Large, rectangular rear support table with integrated transfer balls for easy material handling

- User-friendly 15.6" touchscreen NC control on ergonomic swivel arm

Options:

- Backgauge extensions with 1500, 2500, 3200 or 4200mm length

- Different support table geometries L-, T- or U-shape

- Omega geometry of the lower and upper beam for maximum flexibility in case of barrel plates due to more free space for the workpiece

- 2D or 3D graphic controls

- Fast, servo-motorized sheet thickness adjustment of the bending beam

- Pneumatic upper die clamping of the segmented goad feet

- Central, manual crowning system of the bending beam

- Motorized two-axis backgauge for inclined position

- Manual adjustment of backgauge fingers for inclined position

- Second foot pedal for two-man operation

| Electrical Data | |

|---|---|

| Total input power | 5.7 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

Dr.-Robert-Pfleger-Str. 26

96103 Hallstadt

Deutschland / Germany

info@stuermer-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.