| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

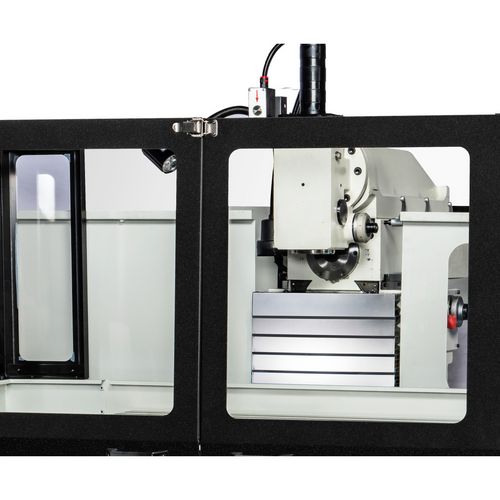

CNC milling machine

OPTImill MZ 4 CNC

High-quality and stable universal tool milling machine with maximum operating comfort

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3511050

Productdetails

- Many-sided range of application

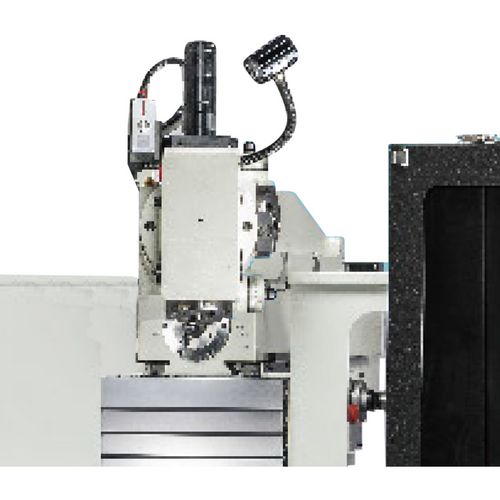

- All important components such as machine structure, column, slide, angle table, cross table and milling tableskopf bodies are made of stress-free MEEHANITE® quality cast iron (FC30), some of them with multiple ribs

- Excellent damping properties and stability of the machine frame

- Servo drive of the X / Y / Z axes

- Stable dovetail guide of the X and Y axes

- Portable, electronic handwheel with enabling switch and emergency stop pushbutton. Much easier to run in programs

- All guides are hardened, ground and additionally coated with Turcite®-B to ensure optimum and constant movement

- All guides adjustable by means of wedge bars

- Ball screw in all axes

- Centrally and clearly arranged operating panel with integrated control system

- Massive cross table, large dimensioned, precisely surface machined, with a high degree of accuracy. Straightened and precision ground

- Milling head ± 45° swiveling

- Coolant device

- Machine lamp

- Smooth running

- Folding table guard with locked safety switch

- Heat exchanger for switch box

- Telescopic covers in all 3 axes

- Automatic central lubrication with lubricating oil and oil quantity control

- Hydraulic tool clamping

Equipment

- Counter bearing for the horizontal spindle

- Hydraulic clamping set (DIN 40-DIN 69871) 95 mm for vertical spindle

- 3 pieces reducing sleeves (MK 1, MK 2, MK 3)

- 3 pieces tightening bolts

- Collet chuck with 7 collets (Ø 6, 8, 10, 12, 16, 20, 25 mm)

- Outer arbor support and long cutter arbor (27 mm) for horizontal spindle

- LED work lamp

- Operating tool

SINUMERIK 828D - The power package in the compact class of CNC controls

First choice for every machining technology

- Modern processor technology and software architecture are the basis of the 80-bit NANOFP accuracy (80-bit floating point accuracy)

- High-quality, robust operator panels made of die-cast magnesium in protection class IP65

- Maintenance-free operator panel front (no fan, battery, hard disk or other components)

- Shopmill: shortest programming time for the production of individual parts and small series

Control system

- The PPU 290 makes multi-touch operation of the SINUMERIK 828 possible. The panel in 15.6" is robust even in rough environments. The SINUMERIK Operate user interface is optimized for touch-sensitive operation.

- Capacitive 15.6" color display in 16th century9 format

- Configurable sidescreen

- Intuitive multi-touch operation

- Full QWERTY keyboard

- Softkey selection via touch function

- Simple data transfer through IP65-protected front interfaces (USB 2.0, RJ45 Ethernet)

- Proximity/distance sensor for smart display control

INCLUDES

- Safety Integrated

- Residual material detection and processing

- SinuTrain: Offline programming station including animated machine control panel realistically

- Manage network drive

- 3-D simulation

- Marking

Functional safety also protects against high costs!

- Avoidance of direct consequential costs of personal injury

- Avoidance of indirect consequential costs of injury

- Increased productivity through increased machine availability: less unplanned downtime and smoother production

- Longer service life of equipment

- Improvement of global competitiveness by increasing the exportability of machinery

| Cooling lubricant system | |

|---|---|

| Coolant pump(s) drive power | 90 W |

| Dimensions and weights | |

|---|---|

| Length approx. | 2186 mm |

| Width/depth approx. | 3005 mm |

| Height approx. | 2069 mm |

| Weight approx. | 1950 kg |

| Drilling/milling output | |

|---|---|

| Max. size milling head | 85 mm |

| Max. size shaft milling cutter | 20 mm |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed | |

|---|---|

| X axis | 5000 mm/min |

| Y axis | 5000 mm/min |

| Z axis | 5000 mm/min |

| Feed speed | |

|---|---|

| X axis | 10 – 2000 mm/min |

| Y axis | 10 – 2000 mm/min |

| Z axis | 10 – 2000 mm/min |

| Horizontal spindle | |

|---|---|

| Spindle chuck | SK 40 DIN 2080 |

| Milling table horizontal | |

|---|---|

| Table length | 500 mm |

| Table width | 900 mm |

| Min. clearance vertical spindle - milling table | 58 mm |

| Max. clearance vertical spindle - milling table | 460 mm |

| T-groove size | 14 mm |

| T-groove number | 7 |

| T-groove spacing | 63 mm |

| Max. load bearing capacity | 320 kg |

| Min. clearance horizontal spindle - milling table | 152 mm |

| Max. clearance horizontal spindle - milling table | 580 mm |

| Milling table vertical | |

|---|---|

| Length | 300 mm |

| Width | 960 mm |

| T-groove size | 14 mm |

| T-groove number | 4 |

| T-groove spacing | 63 mm |

| Precision | |

|---|---|

| Repetition accuracy | ±0.02 mm |

| Positioning accuracy | ±0.02 mm |

| Travel | |

|---|---|

| X axis automatic | 600 mm |

| Y axis automatic | 460 mm |

| Z axis automatic | 395 mm |

| Vertical spindle | |

|---|---|

| Reach | 110 – 560 mm |

| Spindle chuck | SK 40 DIN 69871 |

| Speed range | 48 – 3800 min¯¹ |

| Number of gears | 6 Steps |

| Drive motor output continuous operation S1 | 5.5 kW |

| Drive motor output S6-30 % operation | 9,5 kW |

| Torque drive motor continuous operation S1 | 94 Nm |

| Torque drive motor S6-30 % operation | 120 Nm |

| Quill stroke | 120 mm |

| Quill diameter | 100 mm |

| VPE | 1 |

Packaging unit: 1

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.