| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

Electrode inverter

BOOSTER.PRO 230

Ultra-modern, fully digital electrode welding machine in extremely compact, lightweight design

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 1203230

Productdetails

Basic Features

Method

- Electrode welding

- TIG DC

Description

- Fast, low-induction inverter

- Simple operation via digital SIRIUS operating system with graphic dynamic visualization

- Energy cost-saving IMS inverter technology with adaptation of the current consumption to the voltage curve <

- With its wide-range voltage range, it is suitable for worldwide use

- Fully insulated, protection class 2

- Suitable for generator use

- Works with 100 m mains cable

- Splash water protectedComplies with IP 23

- REHM Pre-Save-System protects the electronics in case of a fall from up to 90 centimeters

- R-Pilot control knob and display shock-resistant

- Equipped with reduced open-circuit voltage (VDR) as standard

- Boost function brings maximum power from single-phase mains

- Fuse hold function serves to monitor the mains for work on weak fuses

- Rehm guarantee

- Quality made in Germany

- Fast, low-induction inverter

- Simple operation via digital SIRIUS operating system with graphic dynamic visualization

- Energy cost-saving IMS inverter technology with adaptation of the current consumption to the voltage curve

- REHM Pre-Save-System protects the electronics in case of a fall from up to 90 centimeters

- Boost function brings maximum power from single-phase mains

| Dimensions and weights | |

|---|---|

| Length approx. | 480 mm |

| Width/depth approx. | 160 mm |

| Height approx. | 320 mm |

| Weight approx. | 6.7 kg |

| Duty cycle | |

|---|---|

| at Imax. 40°C electrode | 40 % |

| at Imax. 40°C TIG DC | 35 % |

| at Imax. 40°C fuse hold | 60 % |

| Current at 100% DC 40°C electrode | 140 A |

| Current at 100% DC 40°C TIG DC | 160 A |

| Current at 100% DC 40°C fuse hold | 140 A |

| Electrical connections | |

|---|---|

| Power consumption in idle mode | < 50 W |

| Electrical Data | |

|---|---|

| Supply voltage | 230 V |

| Mains frequency | 50/60 Hz |

| Power consumption | |

|---|---|

| TIG DC | 5.8 kVA |

| Efficiency | > 80 % |

| Setting range | |

|---|---|

| Electrode | 20 - 180 A |

| TIG DC | 4 – 230 A |

| Fuse hold | 20 – 150 A |

| Standards and certifications | |

|---|---|

| EMC class | A |

| Explanation EMC class | This Class A welding equipment is not intended for use in residential areas where power is supplied by a public low-voltage power supply system. |

| VPE | 1 |

Packaging unit: 1

- No accessories

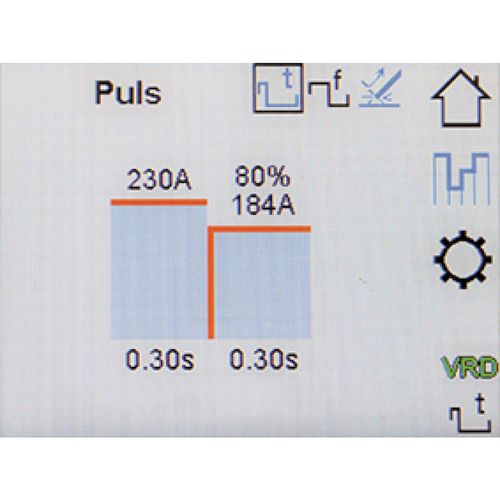

| Electrodes pulse welding | ✔ |

| TIG function | with contact ignition |

| BOOSTER function | ✔ |

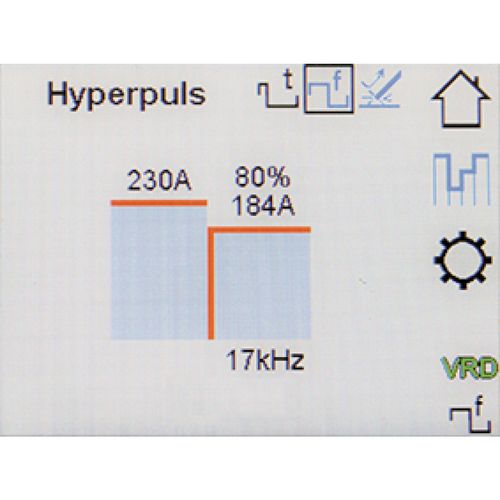

| REHM HYPER.PULS | ✔ |

| Anti-Stick | integrated |

| ArcForce | freely adjustable |

| HotStart | freely adjustable |

| SoftStart | ✔ |

| LiftArc ignition | ✔ |

| VRD operation | ✔ |

| Synergy curves | for basic and rutile electrodes |

| Time pulses | ✔ |

Ottostraße 2

73066 Uhingen

Deutschland / Germany

rehm@rehm-online.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.