| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

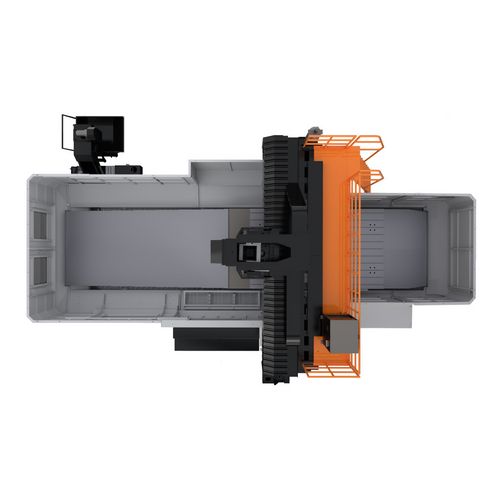

CNC milling machine

OPTImill FP 1325

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3511650

Productdetails

- Perfect structures and robust design guarantee maximum rigidity and stability

- All main components - machine bed, worktable, machine stand, crossbeam, saddle and headstock are made of high-quality MEEHANITE® cast iron

- Generously dimensioned guideways in the X, Y and Z axes

- All guideways are hardened and ground (HRC50 - HRC55)

- The X- and Y-axes are equipped with linear roller guides so that the axes move with maximum precision even at high speeds

- Maximum machining accuracy and high damping thanks to wide, adjustable flat guides on the Z-axis for high drilling and milling performance with high spindle output torque

- Hardened and precision-ground ball screws mounted in high-precision bearings in all three axes for high rapid traverse speeds

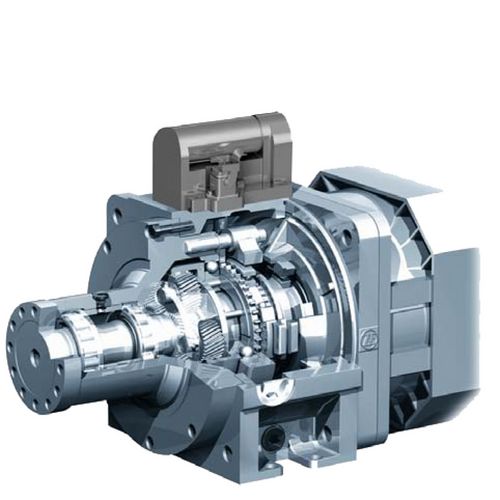

- Cooling of the main spindle gearbox (gears, bearings, spindle) through oil circulation system. Reduction of thermal expansion

- Operating status display (end of work light)

- Axis covers

- LED work lamp with alarm indicator

- Chip conveyor belt design with chip trolley

- Energy chain with tension load and cable separation

- Spindle oil cooler

- Heat exchanger

- BT50 spindle holder with a maximum spindle speed of 6,000 min-1 for high precision

- Pneumatic weight compensation of the Z-axis ensures very high reliability and stability while several axes are working simultaneously. The SCBS system requires no additional power supply or drive. This balance system achieves high speed and high machining precision

- Complete machine enclosure with wide-opening doors for ergonomic workpiece handling

- Automatic lubrication system with pressure control system

- Separation system for lubricating oil and coolant Set-up elements

Equipment options

Tool changer

- Changer driven by precision cam for fast and accurate tool positioning

- The tools are transferred directly from the tool magazine to the spindle during the tool change by means of a double gripper

- The tools are selected bidirectionally via the shortest route.

- The tool magazine is located outside the working area

- The cover on the tool magazine protects the tools from chips or coolant

Z-axis 800 mm

Spindle

- Rigid spindle head

- Automatic compensation system (SCBS) on the spindle head

Y-axis 1650 mm

Column and cross beam

- made from one piece

Base body

- Heavy-duty design and heavily ribbed construction

- Solid one-piece box construction for maximum stability when loading very large workpieces

X-axis 2600 mm or 3100 mm

Working area

- Extra wide work area

SINUMERIK 828D

High-tech for the compact class

The use of two independent tools makes 4-axis turning - balance cutting - possible. The new functions include multi-channel capability with ShopTurn, which allows, among other things, the synchronization of programs with programSYNC. The new software offers the option of running two channels simultaneously in turning and grinding machines.

SINUMERIK CNC controlSinumerik 828D Basic sets standards in all aspects of machining performance. Whether accuracy and speed, reduction of cycle times or energy efficiency and safety - SINUMERIK sets the pace.

Communicative

- Front interfaces: USB 2.0, RJ45 Ethernet, Compact Flash (CF) Card

16 function keys

- The 8 horizontal and 8 vertical softkeys allow you to access all operating screens with just a few keystrokes

User-friendly

- Full QWERTY keyboard

- Hard keys with protective film

- IP65 protection class

Functional safety also protects against high costs!

Machine and system safety is not only important because strict regulations must be observed. When everything runs safely, you benefit from time savings in engineering, higher system availability and greater investment security.

Control system

- 10.4" color display

- 4:3 format

- User-friendly SINUMERIK

- Operate software

System software

- SW 26X5

- MB CNC memory2

- ms block change time100

- Look Ahead256

- tools

Complete package

- Safety Integrated

- Residual material detection and machining

- ShopMill work step programming

- Manage network drive

- 3-D simulation

- Co-drawing

Additional package Siemens OSS PLUS

- 12 months; article no. 3589020

- 24 months; article no. 3589021

- 36 months; article no. 3589022

Information on this additional package and conditions for use can be found at: Material Defects Liability and On-Site Service - SiePortal - Siemens WW

| Cooling lubricant system | |

|---|---|

| Number of coolant pumps | 1 Pc. |

| Coolant pump(s) drive power | 1.35 kW |

| Dimensions and weights | |

|---|---|

| Length approx. | 7800 mm |

| Width/depth approx. | 5550 mm |

| Height approx. | 5000 mm |

| Weight approx. | 22500 kg |

| Electrical connections | |

|---|---|

| Total rated value | 60 kVA |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed | |

|---|---|

| X axis | 10 m/min |

| Y axis | 10 m/min |

| Z axis | 10 m/min |

| Feed motor torque | |

|---|---|

| X axis continuous operation S1 | 80 Nm |

| Y axis continuous operation S1 | 80 Nm |

| Z axis continuous operation S1 | 81 Nm |

| Milling table horizontal | |

|---|---|

| Table length | 2500 mm |

| Table width | 1300 mm |

| Min. clearance vertical spindle - milling table | 160 mm |

| Max. clearance vertical spindle - milling table | 960 mm |

| T-groove size | 22 mm |

| T-groove number | 7 |

| T-groove spacing | 160 mm |

| Max. load bearing capacity | 6000 kg |

| Distance between columns | 1400 mm |

| Precision | |

|---|---|

| Repetition accuracy | ± 0.015 mm |

| Positioning accuracy | ± 0.009 mm |

| Travel | |

|---|---|

| X axis automatic | 2600 mm |

| Y axis automatic | 1400 mm |

| Z axis automatic | 800 mm |

| Min. distance spindle to column | 460 mm |

| Max. distance spindle to column | 460 mm |

| Turret | |

|---|---|

| Design | Double arm gripper |

| Number of tool slots | 24 |

| Max. tool diameter adjacent slots free | 220 mm |

| Max. tool diameter | 110 mm |

| Max. tool length | 350 mm |

| Max. tool weight | 18 kg |

| Tool change time tool to tool (T to T) | 4.5 s |

| Vertical spindle | |

|---|---|

| Spindle chuck | BT 50 |

| Speed range | 6000 min¯¹ |

| Drive motor output continuous operation S1 | 17 kW |

| Drive motor output S6-30 % operation | 32.3 kW |

| Torque drive motor continuous operation S1 | 162 Nm |

| Torque drive motor S6-30 % operation | 330 Nm |

| VPE | 1 |

Packaging unit: 1

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.