| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

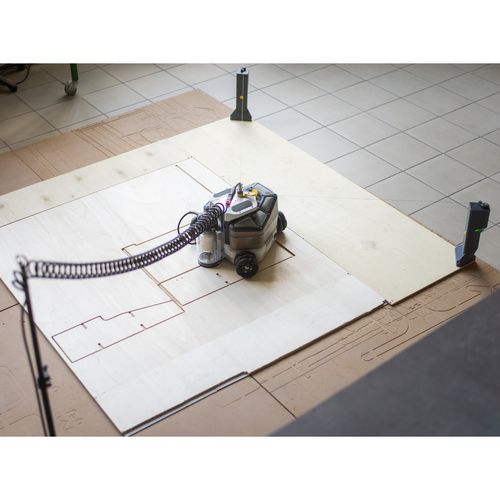

Portable CNC milling robot

Maker

Be your own maker!

3.699,00

EUR excl. Tax / pc(s).

4.401,81

EUR incl. 19% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 5509050

Productdetails

- For flexible, fully automatic processing of workpieces with a diagonal of up to 3.5 m

- Its revolutionary drive and sensor system overcomes the design limitations of stationary CNC milling machines

- Specially designed omnidirectional wheels enable free movement on flat work surfaces without interference from already milled grooves or profiles

- Chips and dust particles are picked up directly by the integrated extraction system and collected in a container

- Precise production of any shape using user-friendly software

- Infinitely adjustable speed

- Can be used anywhere thanks to its low weight

| Spindle speed from to | 13000 33000 min-¹ |

| Clamping diameter max. | 8 mm |

| Tool diameter max. | 8 mm |

| Tool diameter min. | 3 mm |

| Outside collet lenght max. | 58 mm |

| Outside collet lenght min. | 10 mm |

| Maximum raw part width | 1300 mm |

| Maximum raw part length | 2500 mm |

| Maximum raw part thickness | 25 mm |

| Max. Travel speed | 3 m/min |

| Chip container volume | 5 l |

| VPE | 1 |

| Dimensions and weights | |

|---|---|

| Length approx. | 410 mm |

| Width/depth approx. | 410 mm |

| Height approx. | 300 mm |

| Weight approx. | 15 kg |

| Electrical Data | |

|---|---|

| Drive motor power | 1200 W |

| Spindle power | 710 W |

| Current strength | 5.2 A |

| Supply voltage | 230 V |

| Mains frequency | 50/60 Hz |

| Noise emission | |

|---|---|

| Sound pressure level | 85 dB(A) |

| Sound power level | 95 dB(A) |

Packaging unit: 1

- Two tower sensors (length 150 mm, width 150 mm, height 350 mm, weight 0.65 kg each)

- Two USB cables

- Transparent spindle guard

- Mains cable including mains cable stand

ER11 collet chuck - CNC milling cutter 6 mm

- Open-end wrench 17 mm

- Spare carbon brushes for the milling motor

- Control software via download link

| Connection type | USB-B |

Dr.-Robert-Pfleger-Str. 26

96103 Hallstadt

Deutschland / Germany

info@stuermer-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.