| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

TIG inverter

CRAFT-TIG PRO 323 AC/DC PULSE

built in modern inverter technology

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 1364323

Productdetails

- Universally applicable for welding all common types of electrodes

- Ideally suited for assembly work due to protection class IP 21S generally also for outdoor work

- Suitable for use on the generator, for example in workshops, schools, metal construction, on construction sites or for farmers

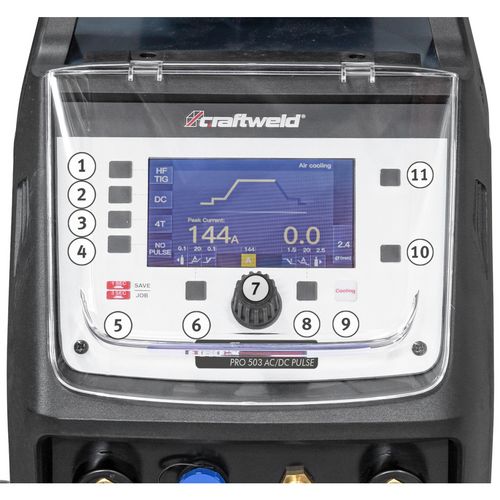

- Precise setting and display of welding parameters via large LC display

- TIG pulsing at 999 Hz enables welding with reduced heat input

- HF high frequency ignition ignites during TIG welding without touching the workpiece

- Equipped with tacking function 0.2 seconds

- Interval welding function with adjustable welding and pause time

- Nine programs can be stored

- Tungsten electrode diameter

- In AC mode adjustable waveforms, balance and frequency

- Water cooling unit 7 liters and trolley as standard equipment

| Device data | |

|---|---|

| Pulse rate | 0.5 – 999 Hz |

| Ignition | high frequency |

| Torch cooling | gas / water |

| Dimensions and weights | |

|---|---|

| Length approx. | 700 mm |

| Width/depth approx. | 260 mm |

| Height approx. | 484 mm |

| Weight approx. | 29.7 kg |

| Duty cycle | |

|---|---|

| at Imax. 40°C TIG DC | 60 % |

| at Imax. 40°C electrode | 60 % |

| Current at 100% DC 40°C TIG DC | 250 A |

| Current at 100% DC 40°C electrode | 250 A |

| Electrical connections | |

|---|---|

| Power consumption in idle mode | < 50 W |

| Electrical Data | |

|---|---|

| Total output | 19.0/16.0 kVA |

| Current consumption TIG AC | 18.7 A |

| Input current TIG DC | 18.9 A |

| Input current electrode AC | 23.5 A |

| Current consumption electrode DC | 24.7 A |

| Supply voltage | 400 V |

| Mains frequency | 50/60 Hz |

| Electrode | |

|---|---|

| Weldable electrodes | 1.6 5.0 mm |

| Power consumption | |

|---|---|

| TIG DC | 9 kVA |

| Electrode | 12.5 kVA |

| Efficiency | 90.48 % |

| Setting range | |

|---|---|

| TIG DC | 10 – 320 A |

| Electrode | 10 – 320 A |

| Standards and certifications | |

|---|---|

| Standard | EN 60974-1:2012, EN 60974-10:2014 |

| EMC class | A |

| Explanation EMC class | This Class A welding equipment is not intended for use in residential areas where power is supplied by a public low-voltage power supply system. |

| VPE | 1 |

Packaging unit: 1

- Ground cable 35 mm² 4 m with 300 A clamp

- TIG torch SR18, 4 m water cooled

- gas hose 12 x 6 mm, 4 m

- Pressure reducer large

| Process MMA | ✔ |

| Process TIG pulsing | ✔ |

| LC display | 5 " |

| Water cooling device | 7 l / 400 V with 1 m connection cable |

| Trolley | with two swivel castors at the front, two fixed castors at the rear and gas bottle holder |

| Single Spot | ✔ |

| Multi Spot | ✔ |

Dr.-Robert-Pfleger-Str. 26

96103 Hallstadt

Deutschland / Germany

info@stuermer-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.